IE University to fabricate 3-D printed protection screens for medics in their fight against Covid-19

IE University's Fab Lab joins the Coronavirus Makers national initiative.

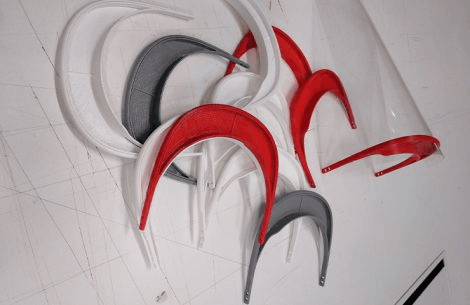

IE School of Architecture and Design will use 3D printers to fabricate the frames for face shields for healthcare personnel in Castilla y León. In doing so, IE joins the Coronavirus Makers initiative made up of more than a hundred individuals from the province of Segovia. “We are grateful to be able to contribute to solving this urgent crisis. We are all looking for ways to help. This is our small way of contributing and we will continue to try to find more ways to support the health authorities and those most in need in the coming days,” explains David Goodman, Vice Dean of IE School of Architecture and Design.

IE students working in the FabLab last year. Photo credit: Roberto Arribas

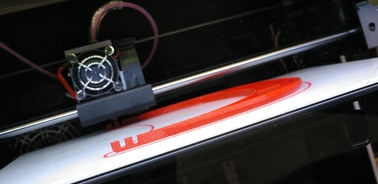

IE students working in the FabLab last year. Photo credit: Roberto ArribasIE University's Fab Lab, the makers laboratory of IE University, will produce the frames for individual face shields over the next 15 days using seven Fused Deposition Modeling 3D printers (FDM) located at its Segovia campus. These face shields, which can be sterilized and therefore reused, will be sent to the Castilla y León Health Service (Sacyl) for distribution in hospitals and nursing homes. The central government’s delegation to the regional government of Castilla y León in Segovia is currently coordinating the delivery of this type of protective equipment.

The Fab Lab IE University, located on the Santa Cruz la Real Campus in Segovia, is part of the global network of laboratories (Fab Lab Network) promoted by the prestigious Massachusetts Institute of Technology (MIT) and the Fab Foundation. promoted by the prestigious Massachusetts Institute of Technology (MIT) and the Fab Foundation. In 2019, the IE School of Architecture and Design lab joined this global network spread over more than 70 countries to facilitate knowledge exchange between students, academics, scientists and researchers.

“We are grateful to be able to contribute to solving this urgent crisis. We are all looking for ways to help.”

The workshop has three laser cutting machines for the fabrication of 2D and 3D structures, a vinyl cutting machine that cuts adhesive material to create posters and logos, nine 3D printers for making highly complex geometric parts, and a large format milling machine (CNC) for making large-scale models, structural prototypes or furniture. The students also have access to a high-resolution mini-milling machine (CNC) for making electronic circuit boards and precision parts, a vacuum thermo-forming machine for creating plastic replicas, and a multitude of traditional carpentry tools for making wooden joints and parts. For many years, IE School of Architecture and Design has been collaborating with the local community of Segovia through DLab projects.